Since the automotive manufacturer Lexus first introduced LED light sources for low beam lights

in 2006, LED use as a light source has developed rapidly in various industries. LED lighting

systems offer high brightness, long-life service, reliable performance, energy savings and many

other advantages. Today, the use of LED headlamps is standard for many medium- and high�configuration vehicle models. This technology has also penetrated the market for various low�configuration models. As vehicles become safer and smarter, LED headlamp systems continue to

evolve, undertaking more functionalities such as ADB, AFS and the integration of multiple sensors

as part of the autonomous driving system. It is anticipated that the rapid development of uses for

LED headlamp systems will continue its momentum, and these types of systems will soon be used

in an even wider range of applications.

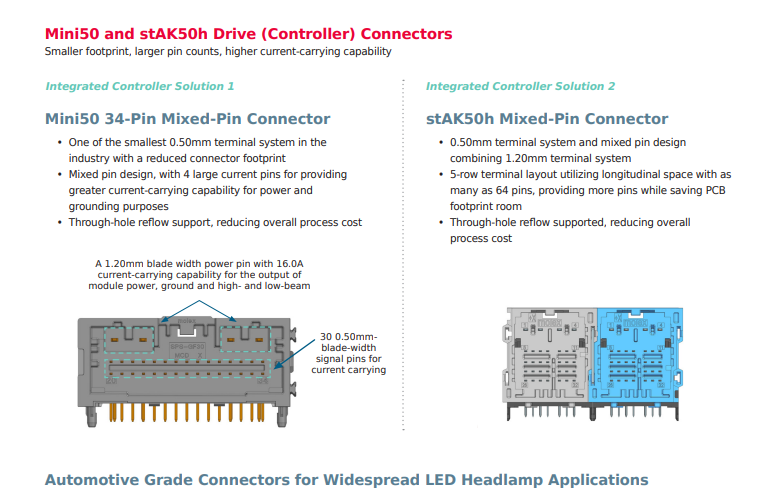

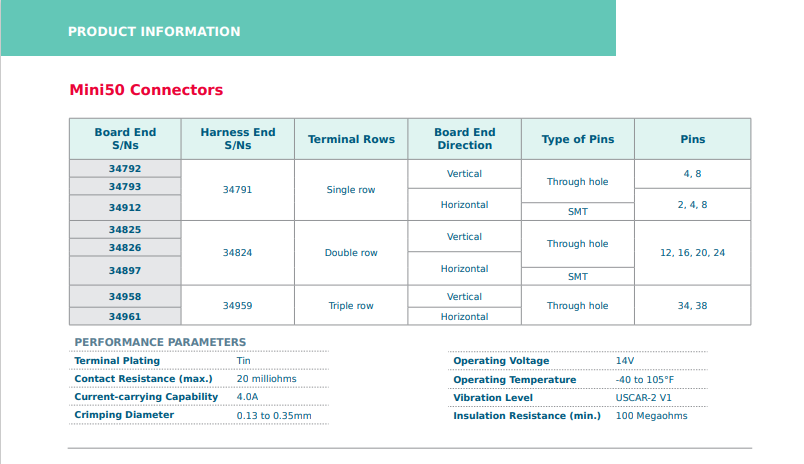

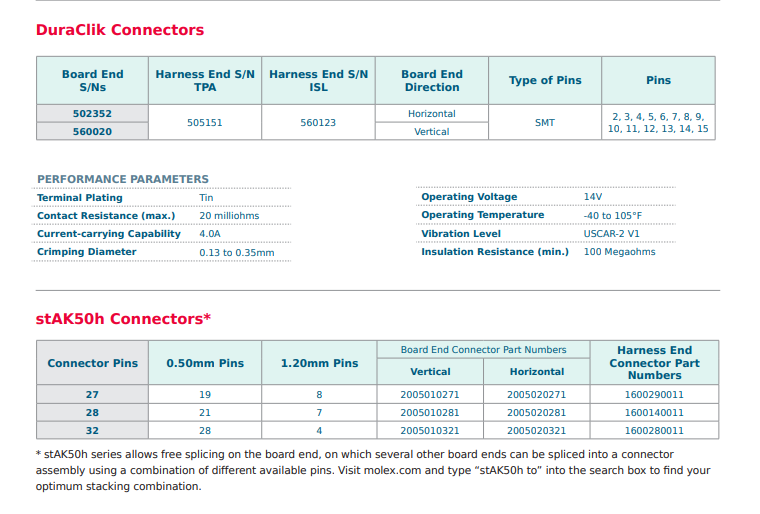

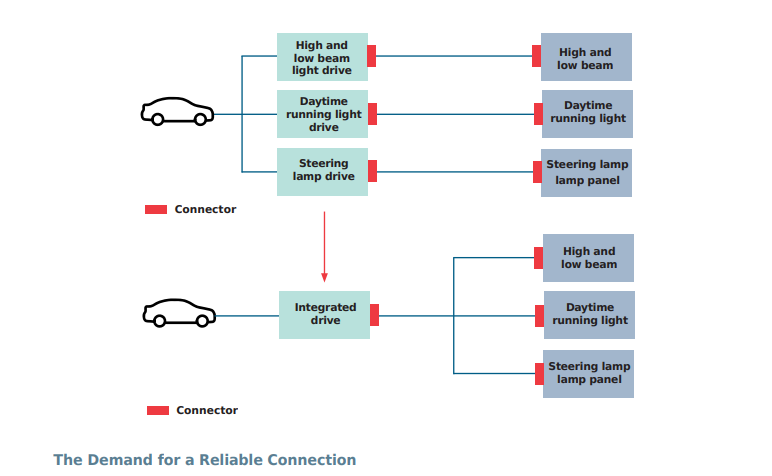

An LED headlamp system is a module comprised of various electrical components that include many connectors. Those connectors

are divided into two categories in terms of their application location: the LED drive (controller) connector and the LED lamp panel

connector. As the LED headlamp evolves, new requirements and challenges arise for the connectors used within them. Those

requirements are primarily of interest in two aspects: first, the pins for LED drive (controller) connector are increasingly in demand

mainly due to the influence of additional functions and the trend of integration; second, the connector footprint is increasingly

shrinking and the shape for LED headlamps is becoming more diversified. In recent years, the appearance of headlamps have

become “sharper,” resulting in more internal space restrictions in the headlamp.

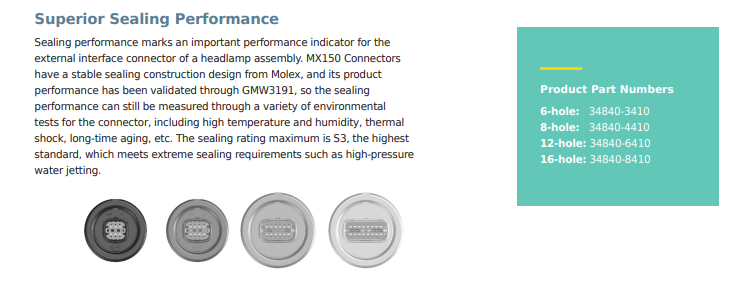

The complex operating environment for the connectors within a car light includes:

• Vehicle vibration, thermal shock, high temperature and humidity

• An operating temperature of at least 105°F, required because of LED heat dissipation

• Sufficient mechanical strength

The connector, therefore, must be subject to rigorous tests, to help ensure reliable electrical connections in

various environments and work conditions.