Helping Boost Electric Vehicle Safety and Mileage

While Saving Comprehensive Costs

Safety, mileage and cost have always drawn the attention of the consumer and the market throughout the development of

electric vehicles. As a result, these are key aspects that call for continuous improvement by carmakers and auxiliary product

suppliers. The battery pack is one of the core components of an electric vehicle. It includes the battery system in the EIC

system and part of the electronic control system. It plays a critical role in the electrical architecture of the vehicle, serving

as the key to improving safety and mileage and reducing costs.

In recent years, battery pack design has been working toward a higher level of safety, while

also becoming more lightweight and compact. On the one hand, battery manufacturers

and automobile assembly plants pursue higher safety levels and more energy density while

reducing comprehensive costs with innovations in anode material and cell integration. On the

other hand, this industry has added new requirements for the electrical connection options

within the battery pack.

For example, to increase safety, the number of monitoring signals in the battery management

system continues growing, and the number of circuit connections required increases

accordingly. Thanks to their light weight, thinness and ease for automated assembly, flexible

printed circuits (FPCs) are gradually replacing traditional cabling and printed circuit boards

(PCBs) in the battery cell’s voltage and temperature monitoring applications. This development

has raised new requirements for connectors, such as being short circuit-proof, miniaturized and

more. Furthermore, those single-function devices that were originally discrete in the battery

pack are evolving into highly integrated comprehensive equipment, increasing demand for

larger-pin-count connectors. To improve assembly efficiency and reduce manufacturing costs,

electrical connection options should facilitate manual operation or be suitable for automatic

assembly.

After listening to our customers and developing a deep understanding of the industry’s pain

points, Molex has responded to new demands from the market, and we have taken into

consideration the characteristics of electrical connection applications within the battery pack.

As a result, Molex has launched connection solutions dedicated to battery pack connectivity,

helping our customers improve product competitiveness.

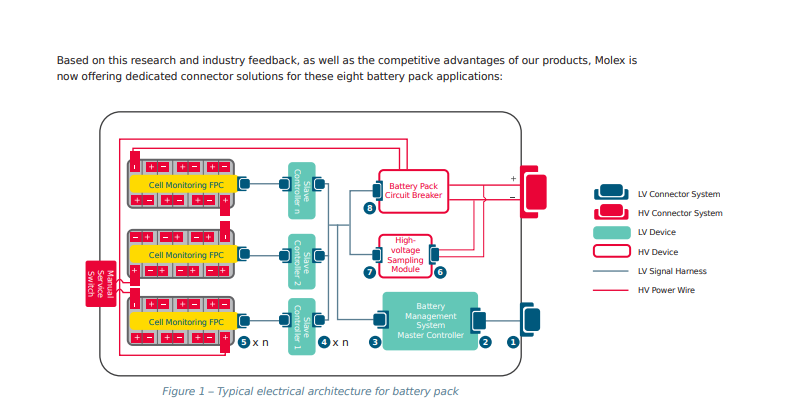

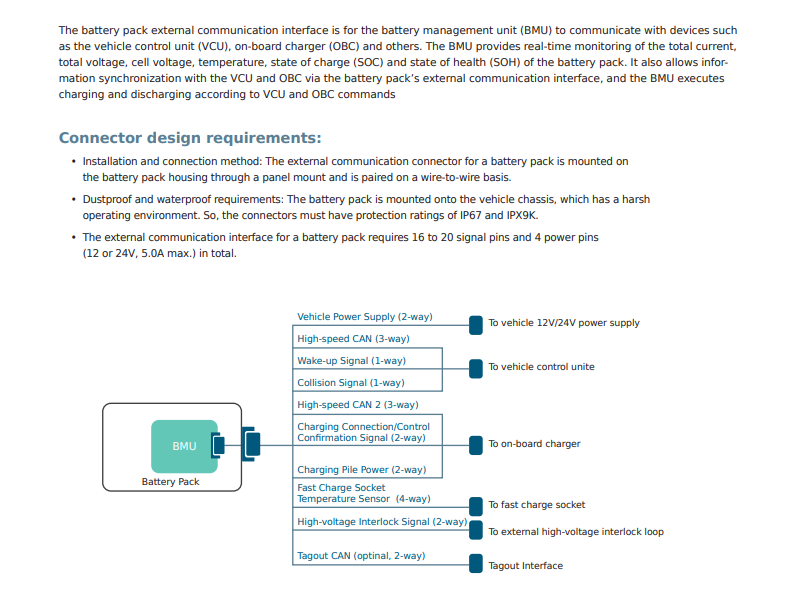

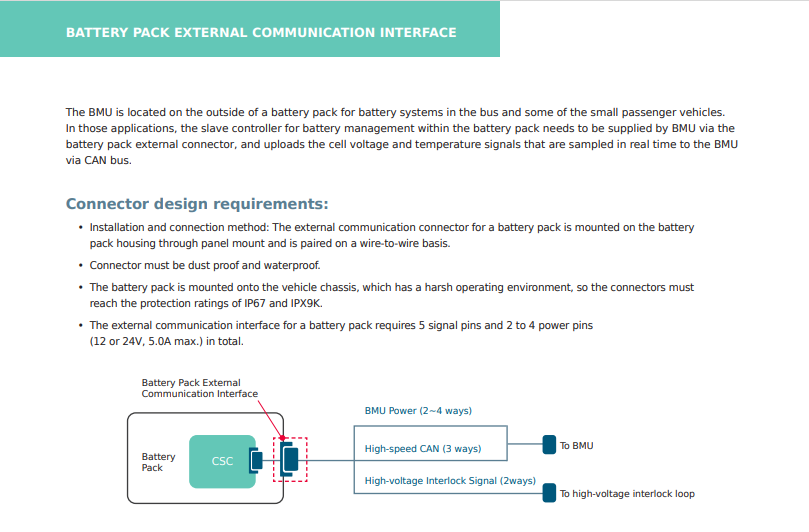

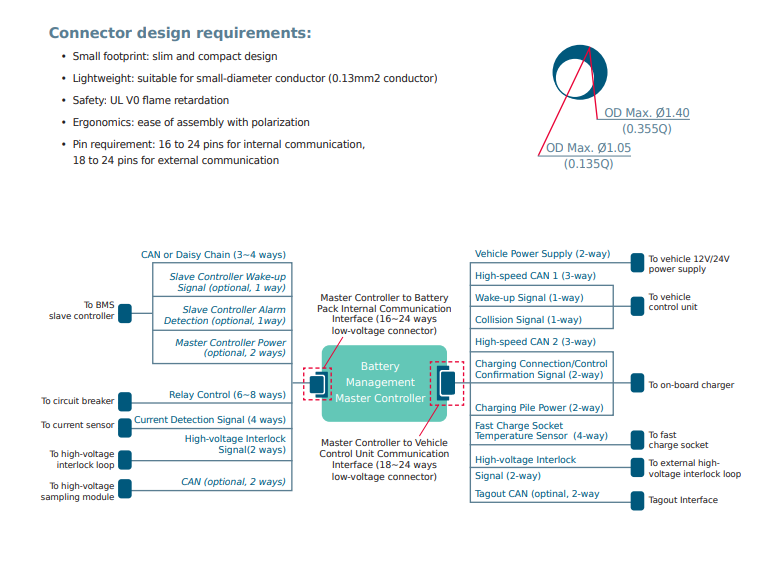

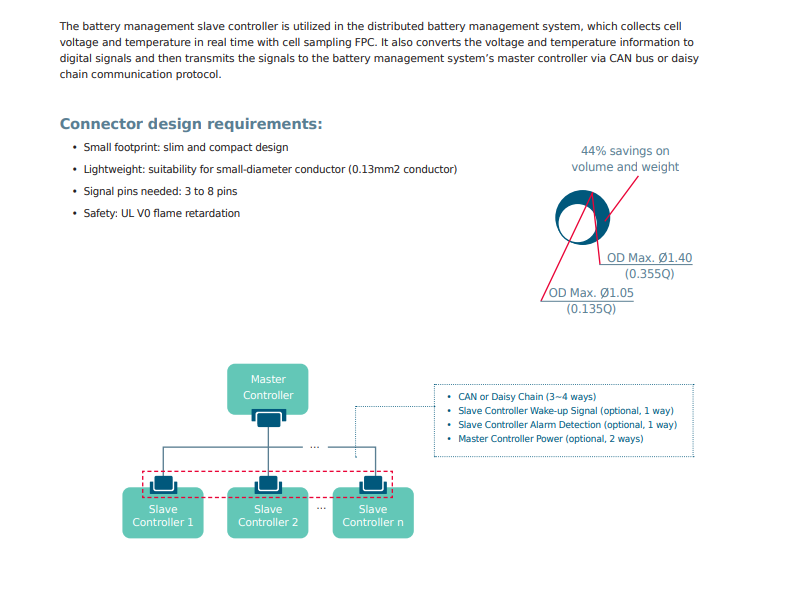

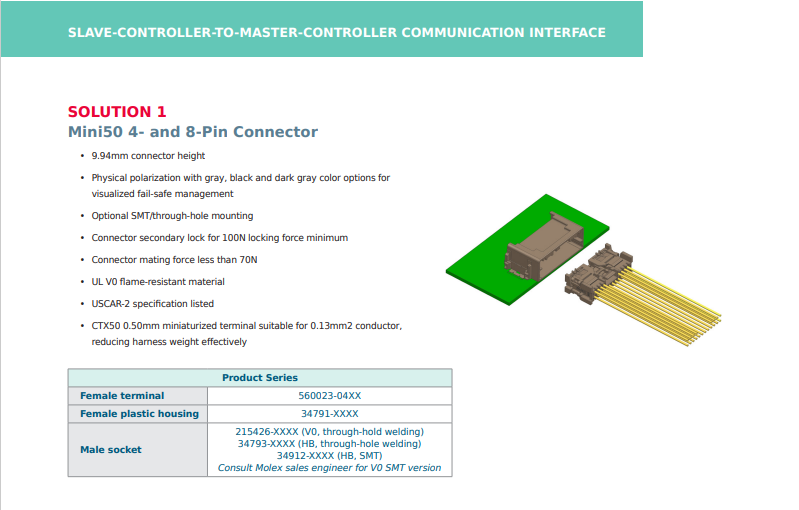

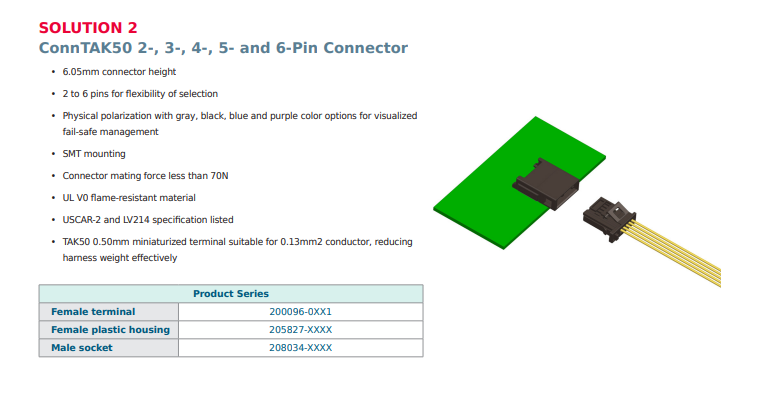

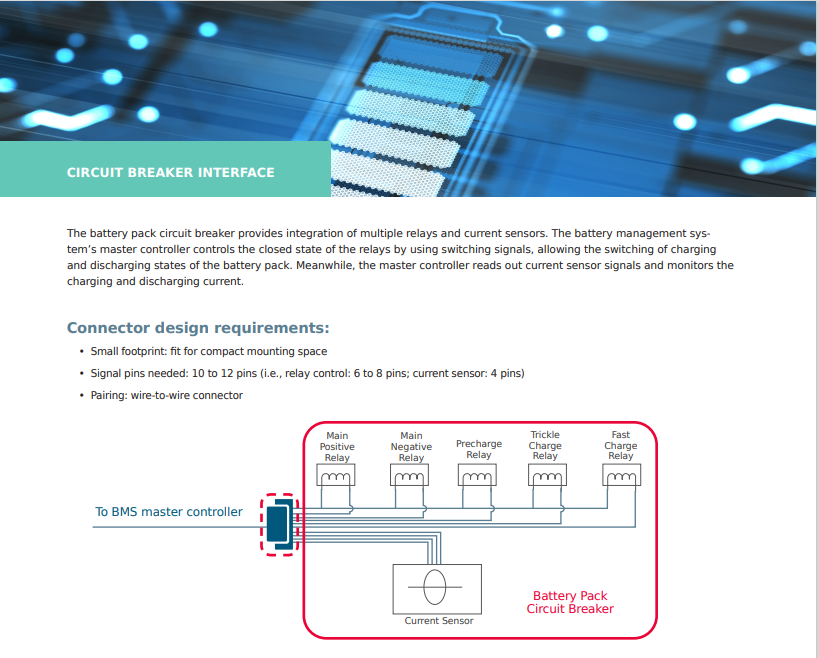

The BMU is the core control unit for a battery pack. Internally, it communicates with a slave controller via a CAN bus or daisy

chain (or is directly connected to the cell sampling circuit). It also monitors cell voltage and module temperature in real time,

and it outputs relay switching signals to the circuit breaker. Additionally, it manages the charging and discharging status for

the battery pack and oversees total voltage, total current and the state of insulation for the battery pack. Externally, the BMU

engages in information interaction with the VCU and OBC, it and it receives the charging and discharging commands from the

VCU and OBC for the battery pack.

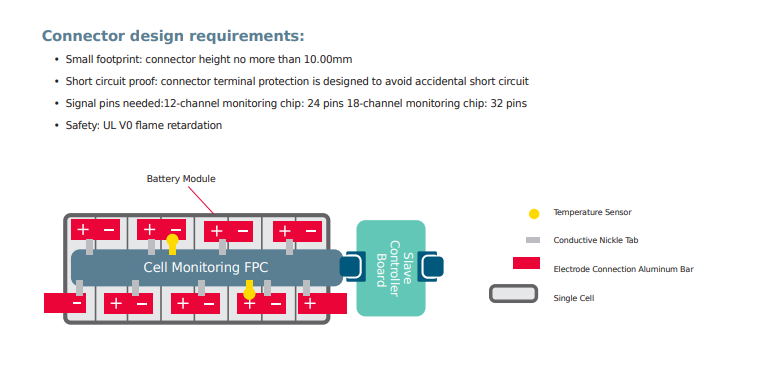

Several individual battery cells form a battery module with a specific method, in series or in parallel, in a battery pack. The cell

monitoring circuit provides real-time sampling and monitoring for the voltage and temperature of individual cells. The battery

management system switches over working status of battery packs according to the monitoring data and provides balancing

control over the cell life. When a cell encounters accidents, such as thermal runaway, the battery management system cuts off

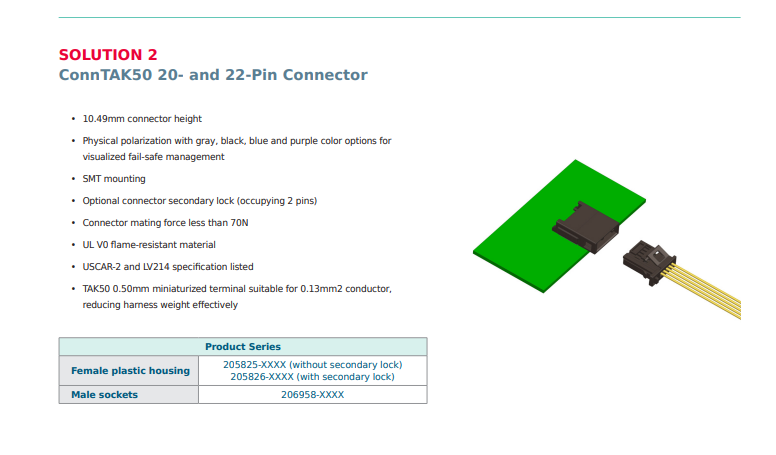

the circuit according to established procedures, reducing the loss. It then reports the fault to the VCU on a timely basis, acquir�ing valuable escape time for people in the vehicle. In this application, an unsealed wire-to-board connector with large pin count

transmits signals. In terms of its footprint, a miniaturized connector is a very effective solution for maximum space savings for

the good of the cell module.